Advanced Solar Photonics Introduces Line of Glass-to-Glass Crystalline Silicon Photovoltaic Modules

Next Generation American Made Modules to Debut at Intersolar North America on July 10-12 in San Francisco

Lake Mary, FL., July 2, 2012, Advanced Solar Photonics, LLC (ASP), an American manufacturer of photovoltaic (PV) equipment and provider of turnkey alternative energy systems, today announced it is introducing a line of next generation glass-to-glass PV modules at Intersolar North America 2012 on July 10-12 at the Moscone Center in San Francisco, CA.

Lake Mary, FL., July 2, 2012, Advanced Solar Photonics, LLC (ASP), an American manufacturer of photovoltaic (PV) equipment and provider of turnkey alternative energy systems, today announced it is introducing a line of next generation glass-to-glass PV modules at Intersolar North America 2012 on July 10-12 at the Moscone Center in San Francisco, CA.

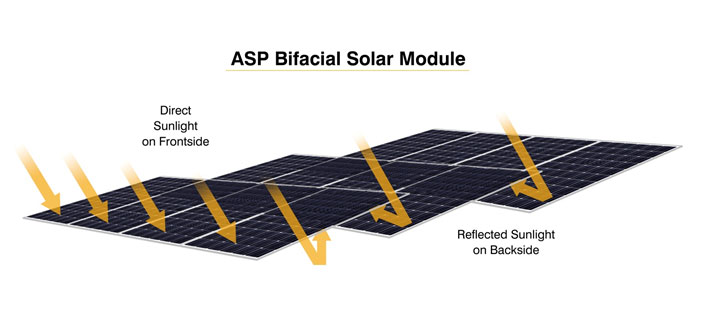

The dual sided glass module (G2G) series will include a range of products featuring bifacial cells, framed and frameless construction, and optical tracking front sheets with micro lenses. G2G PV solar panels feature thinner tempered glass, which reduces the distance light travels, thereby increasing overall module efficiency 10 percent. To further increase efficiency, ASP modules feature a holographic material sandwiched between the silicon and EVA layers maximizing the time per day they can generate electricity from the sun.

“The use of glass-to-glass technology in PV module encapsulation and fabrication is an example of how electricity costs can be hedged through innovation and technology rather than through financial tools, said Lawrence Hefler, spokesman for ASP. The company’s investment in research and development will continue to bring the cost of solar to grid parity making it more economically viable in the US.”

G2G architecture provides dual sided protection of silicon materials from extreme weather conditions. Thinner glass ensures less heat, thermal stability, resistance to impact and elimination of micro fractures. G2G modules are expected to have a usable lifetime of 50 years without danger of mechanical damage or temperature and humidity-related delamination of the back sheet. The glass-to-glass lamination method with no multi-layer back sheet also reduces fire hazard and lessens the probability of mechanical damage over the lifetime of the module.

The highlight of the G2G series on display at Intersolar North America is the bifacial technology that will replace costly axis-based mechanical tracking systems with less expensive optical tracking panels while achieving the same efficiency gains. ASP will be featuring five G2G products along with the ASP 400 Watt series of PV modules in Booth 7029, conveniently located on the first level of Moscone Center in San Francisco. ASP executives and product experts will be on hand to answer questions and exchange information.

###

Advanced Solar Photonics, LLC (ASP), is a manufacturing and R&D center for crystalline silicon solar photovoltaic (PV) panels for utility, commercial and residential applications. Based on the latest cell efficiency, light transmission, and encapsulation technologies, ASP focuses on high-efficiency, state-of-the-art solar PV modules ranging from 200 Watts to 400 Watts. ASP is the second largest producer of crystalline silicon PV panels in the United States and is one of the few producers in the US of Buy American Act compliant products suitable for government, military and municipal projects.

Media Contact:

Corporate Communications

Advanced Solar Photonics, LLC

407-804-1000 x 502

lhefler@aspfab.com

Advanced Solar Photonics Becomes First Net-Zero Solar Powered PV Equipment Manufacturer in North America

1.4 MW Rooftop Solar Installation Generates Enough Energy to Eliminate Electricity Costs

ASP rooftop solar power plant in Lake Mary, Florida

Lake Mary, FL., June 12, 2012 Advanced Solar Photonics, LLC (ASP), an American manufacturer of photovoltaic equipment and provider of turnkey alternative energy systems, today announced it is has become the first net-zero solar powered photovoltaic (PV) equipment manufacturing operation in North America.

A 1.4 MW rooftop solar plant is powering the equipment for the company’s 100 MW production capacity manufacturing plant. This synergy demonstrates a true closed-cycle PV generation and PV module manufacturing project. The solar installation is generating at least as much solar energy as it uses to manufacture the PV equipment. The result is zero net energy consumption and zero carbon emissions annually.

The renewable energy production has eliminated the company’s monthly electricity costs saving hundreds of thousands of dollars annually in operating expenses. “Investing in solar electricity for our own commercial facility allows us to lock in energy costs despite any rate increases” said Glenn Fayer, Chief Financial Officer “We are pre-paying for electricity at a fraction of current and future rates.” The decision to go net-zero was a commitment to use renewable energy to power the factory that makes the photovoltaic solar equipment. The financial payback was added motivation to make that happen.

The rooftop solar system features ASP 240 Watt crystalline silicon PV modules, ASP SunRail™ ballasted racking system, and Solectria Renewable inverters. With more than 5000 solar panels covering the rooftop, the installation will generate 1.6 million kilowatt hours of electricity annually.

Zero net energy consumption supports renewable energy harvesting as a means to cut greenhouse gas emissions. Traditional buildings can consume up to 40% of the total fossil energy. Zero energy buildings are gaining importance and popularity. The zero net energy approach has potential to reduce carbon emissions and reduce dependence on fossil fuels.

###

Advanced Solar Photonics, LLC (ASP), is a manufacturing and R&D center for crystalline silicon solar photovoltaic (PV) panels for utility, commercial and residential applications. Based on the latest cell efficiency, light transmission, and encapsulation technologies, ASP focuses on high-efficiency, state-of-the-art solar PV modules ranging from 200 Watts to 400 Watts. ASP is the second largest producer of crystalline silicon PV panels in the United States and is one of the few producers in the US of Buy American Act compliant products suitable for government, military and municipal projects.

Advanced Solar Photonics to Introduce First Bifacial Glass-to-Glass Photovoltaic Modules Made in America

Solar Panel Innovation Using “Optical Tracking” Technology Increases Energy Harvesting Up To 30 Percent

Lake Mary, FL., May 31, 2012, Advanced Solar Photonics, LLC (ASP), an American manufacturer of photovoltaic equipment and provider of turnkey alternative energy systems, today announced it is introducing the first mono-crystalline bifacial glass-to-glass PV module series made in America.

The bifacial dual sided glass module (G2G) generates more electricity by converting direct, radiant and scattered solar energy on both the front and the back side of the module. The thinner tempered glass means the light does not travel as far, increasing overall module efficiency by 10%. To further increase the efficiency, ASP uses a special holographic material sandwiched between the silicon and EVA layers, maximizing the time per day the modules can generate electricity from the sun. ASP bifacial G2G modules also have a low temperature coefficient, which allows them to produce more electricity than conventional crystalline silicon solar modules at the same temperature. Together these features can result in energy output as much as 30% higher than conventional technology.

“The bifacial G2G technology marks a major turning point in photovoltaic system technology,” said Thomas Gregory, Chief Strategy Officer at ASP. “We’ve replaced costly single-axis and double-axis mechanical tracking systems with much cheaper optical tracking panels and achieved the same efficiency increases.”

Assuming an average system cost of $4/Watt for a conventional fixed ground-mount system, a double-axis tracking system would add about $1/Watt to the installed cost of the system and increase energy generation by approximately 30%. ASP’s bifacial G2G panels will also increase energy generation by about 30% but only add approximately $0.50/Watt to the overall cost of the system. In other words a 12.5% increase in cost will add 30% in energy revenue for system owners.

The glass-to-glass lamination method, with no multi-layer back sheet, results in reduced fire hazard and less probability of mechanical damage over the lifetime of the module. The G2G architecture provides dual sided protection of silicon materials from extreme weather conditions. Thinner glass ensures less heat, thermal stability, resistance to impact and elimination of micro fractures. A frameless construction requires less connections, materials and labor resulting in compact packaging and facilitated transportation. The bifacial G2G modules have a usable lifetime of 50 years without danger of mechanical damage or temperature/ humidity-related delamination of the back sheet, resulting in a loss of energy production performance or outright failure.

This breakthrough PV product is made up of 60 bifacial mono-crystalline silicon cells with up to 20.5% module efficiency on both sides. The total rated power output of the panel will range from 271 Watts to 333 Watts. Bifacial modules are ideally suited for applications with limited ground space such as military bases, municipalities, and schools. In addition, modern rooftop designs using reflective materials for cooling would maximize the harvesting from that enhanced reflectivity.

ASP will be featuring the new bifacial G2G product along with the ASP 400 Watt series of PV modules in their booth on the first level at Intersolar North America on July 10-13, 2012 in San Francisco, CA.

###

Advanced Solar Photonics, LLC (ASP), is a manufacturing and R&D center for crystalline silicon solar photovoltaic (PV) panels for utility, commercial and residential applications. Based on the latest cell efficiency, light transmission, and encapsulation technologies, ASP focuses on high-efficiency, state-of-the-art solar PV modules ranging from 200 Watts to 400 Watts. ASP is the second largest producer of crystalline silicon PV panels in the United States and is one of the few producers in the US of Buy American Act compliant products suitable for government, military and municipal projects.

ASP PV Module Orders Soar after Department of Commerce Ruling on Solar Imports

Countervailing Duties Halt Anti-Competitive Pricing by China-based Manufacturers

Lake Mary, FL., May 23, 2012– Advanced Solar Photonics, LLC (ASP), an American manufacturer of photovoltaic equipment and provider of turnkey alternative energy systems, has seen orders for its PV modules skyrocket with the determination by the U.S. Department of Commerce that China-based solar companies have been dumping products on the US market.

Announced May 17, the anti-dumping investigation of imports of photovoltaic cells found China-based solar companies guilty of selling their products in the US market at prices 31% below cost. The ruling has sent the US solar market into chaos, with many solar developers and installers looking to shore up supply from American solar equipment manufacturers ahead of the imposition of countervailing duties expected later this year.

While the company’s sales of photovoltaic equipment were robust prior to the announcement, ASP’s weekly sales volume has doubled since the Commerce ruling. “The most important thing to know about the ruling is that it will have no impact on the prices we charge for solar equipment,” said Henry Roberts, Director of Strategic Accounts. “While our panels have always been the lowest-priced US product on the market, we’ve never sold equipment below cost.”

Dumping — selling product below cost — has a negative impact on any industry in the medium and long term, because once the manufacturers engaging in predatory pricing have eliminated the competition they are free to raise prices to the maximum level the market will bear. While ASP’s prices won’t increase as a result of the ruling, “capacity could become an issue later in the year,” said Roberts. “Honestly, we’re a bit surprised by the spike in demand.” ASP’s current panel manufacturing capacity is 130 MW per year. The company is currently in the process of raising additional capital to support its capacity expansion.

ASP’s executive management is working closely with investors to help correct a common misunderstanding – that panel production in China costs less than panel production in the United States. Although the cost of labor in China is significantly lower than in the United States, the cost of solar panels is largely a function of raw materials prices, the most important of which – solar silicon – is manufactured predominantly in the United States. In fact, the cost of materials comprises about 90% of the total cost of the panels, while the cost of labor makes up only about 5%. This means any competitive advantage China-based panel manufacturers enjoy due to low labor costs is more than offset by the increased transportation costs of shipping materials and finished goods across the Pacific Ocean.

Although ASP’s panel production costs are at par with its China-based competitors, the company does have several other competitive advantages that have catapulted the company to its leading position in just two short years. Among these are its product quality and its product range – the company is one of only a few global manufacturers that produce 400 Watt panels as well as its own photovoltaic racking systems. The company is part of a vertically-integrated group that also provides system integration and alternative energy supply services.

###

Advanced Solar Photonics, LLC (ASP), is a manufacturing and R&D center for crystalline silicon solar photovoltaic (PV) panels for utility, commercial and residential applications. Based on the latest cell efficiency, light transmission, and encapsulation technologies, ASP focuses on high-efficiency, state-of-the-art solar PV modules ranging from 200 Watts to 400 Watts. ASP is the second largest producer of crystalline silicon PV panels in the United States and is one of the few producers in the US of Buy American Act compliant products suitable for government, military and municipal projects.

Advanced Solar Photonics Increases Capacity to Meet Demand for 400 Watt PV Modules

PV Equipment Manufacturer Expands Production

for Largest Size Solar Panels Made in America

Lake Mary, FL., May 9, 2012– Advanced Solar Photonics, LLC (ASP), a leading provider of full turnkey PV product solutions and manufacturer of crystalline photovoltaic modules, grid-tied inverters, and mounting systems, today announced that it has expanded production of its 400 Watt monocrystalline solar panels manufactured in Florida.

The capacity expansion includes an enhanced production line that features a combined tabbing and stringing machine and the use of robotics to reduce the handling time for solar cells. The process has the latest vision alignment system and non-contact induction soldering to ensure a flawless process. On the line, a string to glass layup system is matched to a stringer machine. An integrated optical monitoring function for cell and string defects helps to reduce any machine downtimes.

The capacity expansion includes an enhanced production line that features a combined tabbing and stringing machine and the use of robotics to reduce the handling time for solar cells. The process has the latest vision alignment system and non-contact induction soldering to ensure a flawless process. On the line, a string to glass layup system is matched to a stringer machine. An integrated optical monitoring function for cell and string defects helps to reduce any machine downtimes.

In addition, the line features a high capacity Meier laminator that encapsulates up to four 96 cell laminates at one time. ASP will be securing an additional high capacity laminator in the third quarter of 2012. The company’s production capacity for 2012 is now 100 MW.

The ASP 400 Watt series is a higher efficiency PV module with 96 monocrystalline cells. In utility scale applications using 400 Watt modules, a project would require less modules, less connectors, less racking, less copper ground wire, and less weeb lugs –all in a smaller footprint. Reduced materials allows for less shipping, less labor and less cost.

###

Advanced Solar Photonics, LLC (ASP), is a manufacturing and R&D center for crystalline silicon solar photovoltaic (PV) panels for utility, commercial and residential applications. Based on the latest cell efficiency, light transmission, and encapsulation technologies, ASP focuses on high-efficiency, state-of-the-art solar PV modules ranging from 200 Watts to 400 Watts. ASP is the third largest producer of crystalline silicon PV panels in the United States and is one of the few producers in the US of Buy American Act compliant products suitable for government, military and municipal projects and meeting the requirements of Section 1605 of the American Recovery and Reinvestment Act of 2009.

Contact:

Advanced Solar Photonics

Corporate Communications

407-804-1000 x502

lhefler@aspfab.com

BlueChip Energy Installs 50kW Solar System for Performance Designs in Deland, Florida

Leading U.S. Parachute Manufacturer to Offset $10,000 a Year in Energy Costs

FOR IMMEDIATE RELEASE

LAKE MARY, FL., March 26, 2012, – BlueChip Energy, LLC (BCE), a fully-integrated solar energy provider for utility, commercial and residential applications, today announced it has installed a 50kW commercial solar power system for Performance Designs, Inc., a world-class parachute designer and manufacturer in Deland, Florida.

The Performance Design rooftop solar array is expected to offset an estimated $10,000 a year in energy costs and reduce ongoing operating expenses at their 40,000 sq. ft. manufacturing and office facility. BlueChip Energy was integral in assisting Performance Designs with their application to the Department of Treasury to secure funds under Section 1603 of the American Recovery and Reinvestment Act (ARRA). This government act provided for a 30% grant payment in lieu of tax credit for renewable energy projects placed in service during 2011.

The Performance Design rooftop solar array is expected to offset an estimated $10,000 a year in energy costs and reduce ongoing operating expenses at their 40,000 sq. ft. manufacturing and office facility. BlueChip Energy was integral in assisting Performance Designs with their application to the Department of Treasury to secure funds under Section 1603 of the American Recovery and Reinvestment Act (ARRA). This government act provided for a 30% grant payment in lieu of tax credit for renewable energy projects placed in service during 2011.

The solar energy project features ASP PV modules, racking system, and components. ASP system components are American-made and manufactured in Lake Mary, Florida. The system will produce 80,000 kilowatt hours annually and help to reduce annual carbon emissions by 36 metric tons.

About BlueChip Energy

BlueChip Energy, LLC (BCE) is a fully-integrated solar PV power generator, occupying all segments of the solar power value chain, from manufacturing of solar panels and balance of systems components, to the sale of turnkey solar power plants – and electricity – to utility, commercial and residential customers. BCE develops finances, constructs, operates, and monitors solar plants for companies and individuals, as well as for its own portfolio.

BlueChip Energy’s two flagship utility scale solar projects, the Rinehart Solar Farm(10 MW) and the Sorrento Solar Farm (40 MW), received approval from the Federal Energy Regulatory Commission (FERC) as self-certified small power production facilities, or Qualified Facilities (QFs) in 2011, requiring the local utility to provide interconnection to them and purchase the electricity they produce. Additionally, these two solar farms have received approval to operate as Exempt Wholesale Generators (EWGs), providing the facilities with undisputed access to the power distribution network. FERC has also granted the company Market-Based Rate Authorization, allowing BCE to purchase and sell wholesale electricity and offer renewable energy products to customers.

BlueChip Energy Receives Completed System Impact Study for Sorrento 100 MW Solar Plant

Progress Energy Florida to Establish Connection to the Transmission System by Year End

LAKE MARY, FL., February 29, 2012, BlueChip Energy, LLC (BCE), a leading solar PV equipment manufacturer, systems integrator and independent power producer, today announced it has received a completed system impact study from Progress Energy Florida for the 100 MW Sorrento Solar plant.

The study results are pending review by the Florida Reliability Coordinating Council, Seminole Electric Cooperative, SECO Energy, and Orlando Utilities Commission. The latter three utilities have transmission buses downstream of the Sorrento Substation. BCE has requested a commercial operation date for the Sorrento Solar Farm to be connected to the transmission system by December 31, 2012.

The current theoretical model of the power grid forecasts that there should be no thermal or voltage violations associated with the interconnection of this plant. There were no projections of transmission breakers identified on the Progress Energy Florida, Inc. (PEF) system that are projected to be pushed above their interrupting rating by the addition of the plant. In the model, the Sorrento Solar plant is projected to not cause power system instability.

Theoretical Voltage stability (P-V curve) analyses were performed under high-import scenario conditions and projections show that the Sorrento Solar Plant should not have a negative impact on the import capability of the State of Florida. The study projections concluded there should be no third-party impacts that would push them beyond their interrupting capability by the interconnection of this plant. The Sorrento Solar site is adjacent to PEF’s Sorrento Substation and will require BCE to build and pay for a new transmission line from BCE’s step-up transformer to the Sorrento bus.

The 100 Megawatt (MW) Sorrento Solar Farm project, currently under construction by BlueChip Energy, LLC, will be one of the largest solar photovoltaic (PV) power plants in the United States. The project – covering 500 acres of open field in Lake County, Florida – BCE is developing the project in two stages, 40 MW and 60 MW. The project site enjoys the economic and engineering benefits of being adjacent to two existing utility substations. Upon completion, 160 million kilowatt hours of clean energy will be generated annually from the power plant.

BlueChip Energy, LLC (BCE) is a fully-integrated solar PV power generator, occupying all segments of the solar power value chain, from manufacturing of solar panels and balance of systems components, to the sale of turnkey solar power plants – and electricity – to utility, commercial and residential customers. BCE develops finances, constructs, operates, and monitors solar plants for companies and individuals, as well as for its own portfolio.

The initial phases of BlueChip Energy’s two flagship utility scale solar projects, the Rinehart Solar Farm (10 MW) and the Sorrento Solar Farm (40 MW), received approval from the Federal Energy Regulatory Commission (FERC) as self-certified small power production facilities, or Qualified Facilities (QFs) in 2011, requiring the local utility to provide interconnection to them and purchase the electricity they produce. Additionally, FERC approved these two solar farms’ status as Exempt Wholesale Generators (EWGs), providing the facilities with undisputed access to the power distribution network. FERC has also granted the company Market-Based Rate Authorization, allowing BCE to purchase and sell wholesale electricity and offer renewable energy products to customers.

Advanced Solar Photonics Introduces Grid-Tied Inverters to PV Equipment Line

American PV Manufacturer Now Provides Complete ASP Brand Turnkey Solar Kit

Lake Mary, FL., February 20, 2012 – Advanced Solar Photonics (ASP), a leading PV equipment manufacturer of crystalline PV solar modules, PV mounting systems, grid-tied inverters, and PV solar system kits for residential, commercial and utility applications today announced it has launched a series of grid-tied inverters.

ASP grid-tied inverters feature industry leading efficiency and voltage operating range that maximizes energy yield and return on investment. The units are designed for residential and small-commercial rooftop or ground mount installations.

With the ASP grid-tied inverters, installation time and costs are greatly reduced through integrating the combiner box, AC/DC disconnects and wire raceway. This unique design simplifies service on the unit through a 2-piece modular configuration which allows the wiring box to remain connected and mounted in the event the power module needs replacing.

ASP inverter models include 3800W, 4000W, 5000W, 6000W and 7000W with a broad operating range of 105 to 500 Vdc for superior performance in low light and high temperature environments. ASP inverters feature a CEC-tested 97% weighted average efficiency along with a transformerless design.

The addition of ASP inverters, along with PV crystalline modules, mounting systems and components allows ASP to provide a complete turn-key solar kit system made in America.

Advanced Solar Photonics, LLC (ASP), a wholly owned subsidiary of BlueChip Energy, is a manufacturing and research and development center for crystalline silicon solar photovoltaic (PV) panels for utility, commercial and residential applications. Based on the latest cell efficiency, light transmission, and encapsulation technologies, ASP focuses on high-efficiency, state-of-the-art solar PV modules ranging from 200 Watts to 400 Watts.

ASP is the third largest producer of crystalline silicon PV panels in the United States and is one of the few producers in the US of Buy American Act compliant products suitable for government, military and municipal projects and meeting the requirements of Section 1605 of the American Recovery and Reinvestment Act of 2009.

BlueChip Energy to Provide Solar Energy Systems for New KB Home Community in Florida

National homebuilder introduces solar power as standard feature in select communities

LAKE MARY, FL., January 30, 2012 BlueChip Energy, LLC (BCE), a fully-integrated solar energy provider for residential, commercial and utility applications today announced it has completed the first residential solar power system for KB Home’s newest community of Built to Order™ homes in Central Florida.

BlueChip Energy will be providing its SunHouse™ solar energy systems for KB Home’s Fisher Plantation 52 home community in Apopka. It will be the first community in the area to include solar power as a standard feature to help KB homeowners reduce their monthly energy bills by as much as 50%. Buyers will have the option to upgrade the standard size of their solar energy system to further reduce or even eliminate their monthly electric bills. Systems sizes will range from the standard 1.44 kW to 5.28 kW.

The initial solar installation on the model home features 22 high efficiency solar panels in a PV system approved by the Florida Solar Energy Center (FSEC). Visitors to Fisher Plantation will be able to see solar energy production in the model home via an online monitoring unit displaying real time system output.

The SunHouse solar system is the company’s complete pre-packaged turnkey system for residential solar installations. The system includes high efficiency crystalline PV modules, mounting systems, and components manufactured locally in Lake Mary, Florida. To date, BCE has completed more than 150 residential and commercial systems in Florida totaling 2 MW.

BlueChip Energy, LLC (BCE) is a fully-integrated solar PV power generator, occupying all segments of the solar power value chain, from manufacturing of solar panels and balance of systems components, to the sale of turnkey solar power plants – and electricity – to utility, commercial and residential customers. BCE develops finances, constructs, operates, and monitors solar plants for companies and individuals, as well as for its own portfolio.

BlueChip Energy’s two flagship utility scale solar projects, the Rinehart Solar Farm (10 MW) and the Sorrento Solar Farm (40 MW), are approved by the Federal Energy Regulatory Commission (FERC) as self-certified small power production facilities, or Qualified Facilities (QFs) in 2011, requiring the local utility to provide interconnection to them and purchase the electricity they produce. Additionally, these two solar farms are approved to operate as Exempt Wholesale Generators (EWGs), providing the facilities with undisputed access to the power distribution network. FERC has also granted the company Market-Based Rate Authorization, allowing BCE to purchase and sell wholesale electricity and offer renewable energy products to customers.

BlueChip Energy Signs 300 Acre Land Lease Agreement with City of Eustis, Florida

Resolution Paves the Way for Development of 60 MW Solar Farm Expansion in Lake County

Lake Mary, FL– January 10, 2012 – BlueChip Energy, LLC (BCE), a fully-integrated solar energy provider for utility, commercial and residential applications, today announced the signing of a land lease agreement with the City of Eustis in Lake County for 300 acres of land to be developed into a 60 MW solar farm.

The 300 acres property is adjacent to the 40 MW Sorrento Solar Farm now under construction. The combined solar farm of 100 MW will become one of the largest solar power plants in the U.S. upon completion. BlueChip Energy previously secured connection to the power grid through agreements with Progress Energy and SECO.

“This agreement is beneficial for both the City and BlueChip,” said Paul Berg, Eustis City Manager. “It provides BlueChip a location with immediate access to the grid, and the City benefits from using alternative energy source to power its water and wastewater facility as a portion of BlueChip’s lease payment. Ultimately, the lease will provide over $150,000 in payments to the City for the use of the property, and the energy provided will be fully renewable over a long period of time.”

A resolution of the City Commission of the City of Eustis authorized the mayor to execute a commercial lease with BCE for a wastewater spray field property. The city owns the 300 acres of land and no longer needs all of the property for spraying.

BlueChip Energy, LLC (BCE) is a fully-integrated solar PV power generator, occupying all segments of the solar power value chain, from manufacturing of solar panels and balance of systems components, to the sale of turnkey solar power plants – and electricity – to utility, commercial and residential customers. BCE develops finances, constructs, operates, and monitors solar plants for companies and individuals, as well as for its own portfolio.

BlueChip Energy’s two flagship utility scale solar projects, the Rinehart Solar Farm (10 MW) and the Sorrento Solar Farm (40 MW), received approval from the Federal Energy Regulatory Commission (FERC) as self-certified small power production facilities, or Qualified Facilities (QFs) in 2011, requiring the local utility to provide interconnection to them and purchase the electricity they produce. Additionally, these two solar farms have received approval to operate as Exempt Wholesale Generators (EWGs), providing the facilities with undisputed access to the power distribution network. FERC has also granted the company Market-Based Rate Authorization, allowing BCE to purchase and sell wholesale electricity and offer renewable energy products to customers.